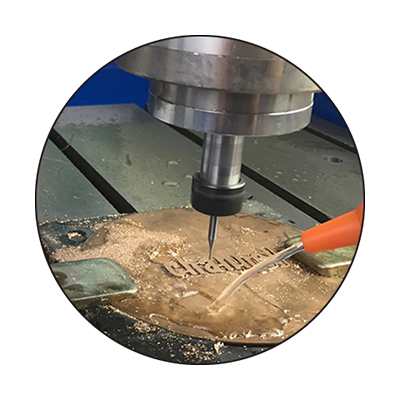

Mold and Die Making: Engraving cavities and textures into molds for plastic injection, die-casting, or glass making.

PCB (Printed Circuit Board) Manufacturing: Precise milling of copper boards to create circuit prototypes and small-batch production.

Functional Parts: Manufacturing precise, non-load-bearing parts from engineering plastics, epoxy boards, or soft metals for prototypes, fixtures, and jigs.

Main specifications

★ Marble structure

★ Professional metal working 2.2kw water cooling spindle

★ Syntech controller with ethernet port

★ Abosolute value syntech servo motor

★ Square linear rails confirm higher precision

★ High precision C5 ballscrew transimit

| Model | 4040MB | 6060MB |

| XYZ axis travel | 400x400x150mm | 600x600x150mm |

| Feeding height | 150mm | 150mm |

| Table size | 440x440mm | 660x660mm |

| Spindle | 2.2kw water cooling (0-24000RPM) | |

| Rail type | Square rail | |

| Control system | 3Axis MDR ( Ethernet port) | |

| Motor | Stepper motor | |

| Transmit | Ballscrew | |

| Table type | Marble structure | |

| Max travel speed | 8000mm/min | |

| Working precision | 0.05mm | |

| Voltage | AC220V±10% / 50~60Hz | |

| Compatible Software | Type3/Artcam/UG/Pro-E/Mastercam/Ucancam etc | |

| Command code | G code | |

| Machine size (L*W*H) | 710*820*1320mm | 1050*1120*1320mm |

| packing size (L*W*H) | 880*940*1520mm | 1170*1120*1520mm |

| Net/Gross weight | 400kg / 450kg | 500kg / 550kg |

|

|

|

|

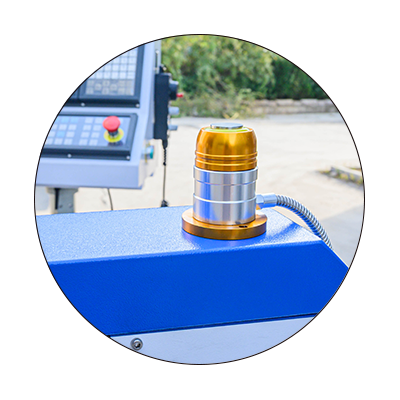

| Professional metal 2.2kw water cooling spindle | Marble structure | Syntech controller | Tool sensor |

|

|

|

|

| Syntech absolute value Servo motor | Square rails | High precision ballscrew | Flood tool cooling system |

Jinan Chentuo CNC Equipment Co., Ltd. presents the Marble version 4040-6060, a cutting-edge Metal CNC solution engineered to redefine precision and efficiency in modern manufacturing. Designed for B2B clients seeking reliable, high-performance machining tools, this versatile system combines robust construction with advanced technology to meet the demands of diverse industrial applications. Whether processing soft metals, composites, or stone materials, the Marble version 4040-6060 delivers consistent results that elevate production standards while reducing operational costs.

The Marble version 4040-6060 stands out with a suite of features tailored for industrial reliability and precision. At its core is a heavy-duty cast iron frame that minimizes vibration during high-speed operations, ensuring stability even under continuous workloads . This rigid structure supports XYZ working travels of 400×400×200mm (4040 model) and 600×600×200mm (6060 model), with a maximum feed height of 200mm to accommodate large workpieces . Equipped with a 2.2KW high-speed water-cooled spindle (from Changzhou Qiancheng), the Marble version 4040-6060 operates at 6000-24000rpm, providing efficient heat dissipation for extended machining sessions without compromising precision .

Precision is further enhanced by premium components, including Taiwan-imported TBI ball screws and HIWIN/CSK linear guide rails . These parts ensure smooth, low-friction movement across all axes, delivering a repeat positioning accuracy of ±0.01mm and engraving accuracy of 0.03mm—critical for intricate designs and tight tolerances . The Marble version 4040-6060 also offers flexible tool compatibility, accepting tool shank diameters from 3.175mm to 12.7mm, and supports optional 4th-axis rotation for 3D machining of cylindrical workpieces up to 160mm in diameter . Intuitive control options, including Ncstudio or DSP handheld systems, simplify programming and operation, while compatibility with industry-standard software (Artcam, Type3, CAD) ensures seamless integration into existing workflows .

The Marble version 4040-6060’s adaptability makes it indispensable across multiple sectors, with key applications including:

Jinan Chentuo CNC Equipment Co., Ltd. leverages years of expertise in metal CNC technology to craft the Marble version 4040-6060, a machine that balances performance, durability, and affordability. Every unit undergoes rigorous quality control to meet international manufacturing standards, ensuring it can withstand the rigors of daily industrial use. The Marble version 4040-6060’s modular design allows for customization—whether adding a 4th axis, upgrading the spindle, or integrating specialized tooling—to match specific production needs.

For businesses aiming to enhance efficiency, reduce costs, and deliver superior quality, the Marble version 4040-6060 is more than a machining tool—it’s a strategic investment in long-term growth. Its ability to handle diverse materials and applications makes it a versatile workhorse, while its precision and reliability ensure consistent results that impress clients and drive repeat business. Trust Jinan Chentuo to provide not just a machine, but a comprehensive solution backed by responsive technical support and industry-leading warranty coverage.

Granite (typically natural granite or polymer concrete/composite granite) is a premium material used for bases and critical components in ultra-precision machine tools, measuring systems (like CMMs), and semiconductor equipment. Its advantages stem from its unique physical properties compared to cast iron or steel.

Key Benefit: Superior Surface Finish.

Granite has an internal damping capacity 6 to 10 times higher than cast iron. It rapidly absorbs vibrations from cutting forces, spindle operation, and external sources, minimizing chatter. This results in mirror-like surface finishes and protects the tool life.

Key Benefit: Unmatched Accuracy Over Time and Temperature.

Granite has a very low coefficient of thermal expansion (about 1/3 that of cast iron). It reacts slowly and minimally to ambient temperature fluctuations, reducing thermal drift. This ensures consistent positioning and geometric accuracy, crucial for long-duration, high-tolerance machining.

Key Benefit: Permanence of Calibration.

Natural granite is geologically stress-relieved. Polymer concrete casts also exhibit minimal residual stress. Unlike metal castings, which can warp over years due to stress relaxation, granite structures maintain their shape and alignment almost indefinitely, ensuring the machine's foundation stays true.

Key Benefit: Low Maintenance & Durability.

Granite is non-porous, chemically inert, and rust-proof. It resists coolants, oils, and humidity. The surface is also highly wear-resistant, protecting critical reference planes (like guideway mounting surfaces) from degradation.

Key Benefit: Ideal for Specialized Applications.

Granite is non-magnetic and an electrical insulator. This is critical for machines used in MRI component manufacturing, electronics, or any environment where magnetic interference or stray currents must be avoided.

Ultra-Precision Machine Tools: Jig boring machines, diamond turning lathes, high-end grinding machines.

Coordinate Measuring Machines (CMMs): The industry standard base material for its stability.

Metrology Equipment: Optical flats, inspection plates, surface plates.

Semiconductor & Electronics Manufacturing: Wafer steppers, photolithography stages.

Lower Tensile Strength: Granite is brittle and cannot withstand high bending or tensile loads. Design must prioritize pure compression.

Complex Manufacturing: Machining and installing metal inserts (for fasteners, guideways) require specialized expertise and epoxy techniques.

Weight: While advantageous for mass, it makes the structure less portable.

Cost: Material and fabrication processes are typically more expensive than cast iron.

In summary, the granite structure is not about brute force strength, but about providing an incredibly stable, quiet, and thermally inert foundation. This allows the spindle, drives, and tool to perform at their ultimate precision potential, making it the material of choice for the most demanding micron- and submicron-level applications.

Copyright © 2025 by Jinan Chentuo CNC Equipment Co.,Ltd. — Privacy Policy