Main specifications

| Model | SM-1325MF-4 Multi-function |

| XYZ axis travel | 1300x2500x120mm |

| Feeding height | 120mm |

| ATC tool type | 8 PCS linear type( back side) |

| Multi-function | 1. 4.5kw water cooling ATC spindle |

| 2. Oscillating knife | |

| 3. V-cut knife | |

| 4. Camera (CCD) | |

| Rail type | linear rails XYZ 20mm |

| Control system | MDR |

| Drive type | Servo motor with shimpo reducer |

| Transmit | X Y Oblique gear rack /Z ballscrew |

| Table type | Vacuum absorption with T slot clamping with 5.5KW vacumm pump |

| Max travel speed | 5000mm/min |

| Working precision | 0.05mm |

| power | AC380V±10% /50~60Hz |

| Compatible Software | Type3/Artcam/UG/Pro-E/Mastercam/Ucancam/Powermill.. etc |

| command code | G code |

| Machine size | 3150*2020*1650mm |

| packing size | 3290*2160*1840mm |

| Net/Gross weight | 1300kg/1500kg |

Jinan Chentuo CNC Equipment Co., Ltd., a trusted expert with 16+ years of CNC engineering experience, proudly presents the 1325MF-4 — a robust Multi-Function CNC machine designed to empower B2B partners across diverse industries. Built to blend precision, versatility, and reliability, this machine excels in cutting, engraving, milling, and marking a wide range of materials, making it a one-stop solution for businesses aiming to streamline workflows and boost productivity. Whether you’re in woodworking, advertising, or decoration, the 1325MF-4 delivers consistent, professional results that meet global quality standards, backed by our commitment to superior craftsmanship and responsive customer support.

As a top-tier Multi-Function CNC machine, the 1325MF-4 is engineered with features that prioritize adaptability and performance. It boasts an optimized XYZ axis travel of 1300x2500x200mm, paired with a spacious 1300x2500mm table size — providing ample room to handle large workpieces (like full-size wood panels or acrylic sheets) or process multiple small projects in a single run. The 200mm feeding height accommodates thick materials such as solid wood, MDF, aluminum plates, and PVC foam sheets, ensuring flexibility for diverse project requirements.

At its core, the 1325MF-4 is equipped with a 3kw water-cooling spindle (0-24000 RPM), delivering steady power for smooth cutting and intricate engraving without overheating — a critical advantage for prolonged production sessions. Its precision square rail system, combined with a high-torque servo motor drive, guarantees stable, vibration-free movement, which is essential for maintaining clean edges and sharp details on various materials. The machine also features an intuitive control system that supports seamless CAD/CAM integration, allowing operators to program complex designs (from simple cuts to detailed relief engravings) with ease. Every component of the 1325MF-4 undergoes rigorous quality testing, from the reinforced table structure to the dust-resistant spindle housing, ensuring it withstands the demands of daily high-volume industrial use.

The 1325MF-4 is a dynamic Multi-Function CNC machine that adds value to multiple industries, making it an indispensable tool for:

At Jinan Chentuo CNC Equipment Co., Ltd., we support the 1325MF-4 with comprehensive pre-sales and after-sales services, including free remote troubleshooting, on-site training, and insured shipping to 60+ countries. Our partnerships with 200+ enterprises worldwide reflect the reliability and performance of the 1325MF-4. This Multi-Function CNC machine isn’t just a tool — it’s a strategic investment that helps your business stay competitive in the fast-paced industrial market. Choose the 1325MF-4 and experience the difference a high-performance, versatile CNC machine can make for your production capabilities.

|

|

|

|

|

|

4 functions controller Special design controller for This 4functions machine.Independent each axis, extremely effective. |

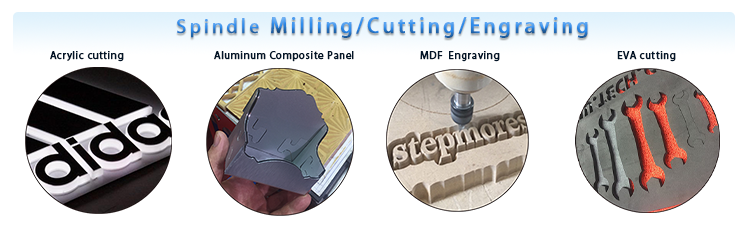

4.5kw ATC water cooling spindle Speed 24000 RPM BT30 tool holders ER32 collets:25mm tool max

|

Oscillation and tangential knife Designed for cutting soft material like leather ,fabric .pvc .plastic film..etc

|

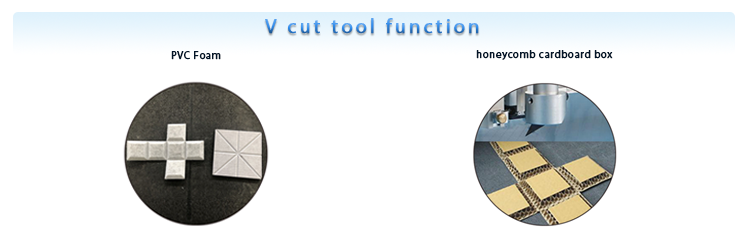

V cut |

|

|

|

|

|

|

CCD Camera Find mark point to match design position of each cutting outlines |

Linear tool changer 8pcs tool holders |

High precision tool sensor Can get each different tool length offset . 0.001mm tolerance precision will help ATC machine work perfect |

Tool holder lock device Can help user change tool bits easily. |

|

|

|

|

|

|

Servo motor Offer high precision controller of each movement. Less vibration and less noise help CNC machine do best performance. |

Shimpo reducer from Taiwan Instead of cheap cost belt gear box. It has more rigidity power. Higher precision and stability ,Help servo motor do better performance. |

Vacuum table Multi-zoned allows the operator to easily switch from full sheet processing to smaller part processing. |

Vacuum zones control valve User can control which vacuum zone open or close by these valves |

|

|

|

|

|

|

Linear square guide ultra-heavy type that achieves a deep grooved raceway with its diameter more approximate to the ball diameter |

Helical tooth rack on XY axis Helical Gear is featured as much lower noise and more steady meshing. |

Ballscrew on Z axis High precision is required to meet the C7 standard, ensuring the machine milling achieves the correct dimensions. |

Central Lubricator Central Lubricator: Easier to lubricate the Guide units regularly,just pull it gently and oil will go when it is needed. |

Copyright © 2025 by Jinan Chentuo CNC Equipment Co.,Ltd. — Privacy Policy