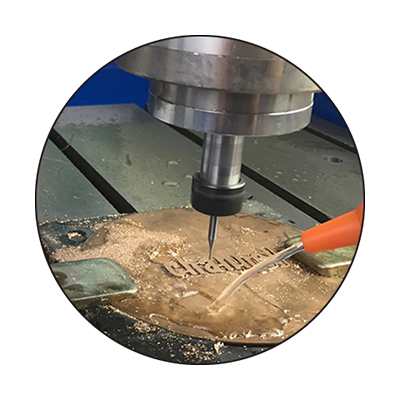

1.Advertisment industry:Acrylic,PVC,ABS plate,aluminum plate

2.General wood working industry:furniture decoration,instrument manufacturing,wooden craft,solid wood furniture,MDF

3.Decoration industry:art model,mural,screen,gift packing

4.Mould industry:casting,spaceflight,craft,rail traffic

Main specifications

★ 2.2kw ATC water cooling spindle

★ PC controller with ethernet connection port

★ Easy servo motor

★ Vacuum table / dust collector option

★ Dust collector

★ High precision ballscrew transimit

| Model | 6090ATC | 6012ATC | 6015ATC |

| XYZ axis travel | 600x900x180mm | 600x1200x180mm | 600x1500x180mm |

| Feeding height | 200mm | 200mm | 200mm |

| Table size | 600x1250mm | 600x1550mm | 600x1850mm |

| Spindle power | 2.2kw ATC water cooling(0-24000RPM) | ||

| ATC tool type and number | 4pcs linear type tool changer on side | ||

| Control system | PC control system(Ethernet cable) | ||

| Drive type | Easy servo driver | ||

| Rail type | linear rails | ||

| Transmit | ballscrew | ||

| Table type | Vacuum table with 2.2kw pump | ||

| Dust collector | Single bag dust collector with auto up-down boot | ||

| Max travel speed | 8000mm/min | ||

| Working precision | 0.05mm | ||

| Power | AC220V±10% / 50~60Hz | ||

| Compatible Software | Type3/Artcam/UG/Pro-E/Mastercam/Ucancam etc | ||

| Command code | G code | ||

| Machine size (L*W*H) | 1400*1350*1540mm | 1670*1350*1540mm | 1970*1350*1540mm |

| packing size (L*W*H) | 1540*1490*1740mm | 1810*1490*1740mm | 2110*1490*1740mm |

| Net/Gross weight | 300kg / 350kg | 350kg / 400kg | 400kg / 450kg |

| Model | 1212ATC | 1215ATC | 1218ATC |

| XYZ axis travel | 1200x1200x180mm | 1200x1500x180mm | 1200x1800x180mm |

| Feeding height | 200mm | 200mm | 200mm |

| Table size | 1300x1250mm | 1300x1520mm | 1300x2150mm |

| Spindle power | 2.2kw ATC water cooling(0-24000RPM) | ||

| ATC tool type and number | 4pcs linear type tool changer on side | ||

| Control system | MDR controller | ||

| Drive type | Easy servo driver | ||

| Rail type | linear rails | ||

| Transmit | ballscrew | ||

| Table type | Vacuum table with 2.2kw pump | ||

| Dust collector | Single bag dust collector with auto up-down boot | ||

| Max travel speed | 8000mm/min | ||

| Working precision | 0.05mm | ||

| Power | AC220V±10% / 50~60Hz | ||

| Compatible Software | Type3/Artcam/UG/Pro-E/Mastercam/Ucancam etc | ||

| Command code | G code | ||

| Machine size (L*W*H) | 1690*2090*1540mm | 1720*2090*1540mm | 2020*2090*1540mm |

| packing size (L*W*H) | 1830*2230*1740mm | 1860*2230*1740mm | 2160*2230*1740mm |

| Net/Gross weight | 500kg / 550kg | 600kg / 750kg | 700kg / 850kg |

| Model | 9012ATC | 9015ATC |

|---|---|---|

| XYZ axis travel | 900x1200x180mm | 900x1500x180mm |

| Feeding height | 200mm | 200mm |

| Table size | 1300x1250mm | 1300x1520mm |

| Spindle power | 2.2kw ATC water cooling(0-24000RPM) | |

| ATC tool type and number | 4pcs linear type tool changer on side | |

| Control system | MDR controller | |

| Drive type | Easy servo driver | |

| Rail type | linear rails | |

| Transmit | ballscrew | |

| Table type | Vacuum table with 2.2kw pump | |

| Dust collector | Single bag dust collector with auto up-down boot | |

| Max travel speed | 8000mm/min | |

| Working precision | 0.05mm | |

| Power | AC220V±10% / 50*60Hz | |

| Compatible Software | Type3/Artcam/UG/Pro-E/Mastercam/Ucancam etc | |

| Command code | G code | |

| Machine size (L*W*H) | 1670*1650*1540mm | 1970*1650*1540mm |

| packing size (L*W*H) | 1810*1790*1740mm | 2110*1790*1740mm |

| Net/Gross weight | 400kg / 500kg | 500kg / 550kg |

As a leading manufacturer in the CNC industry, Jinan Chentuo CNC Equipment Co., Ltd. brings over 16 years of expertise to the table with our ATC Function Middle Size CNC Machines. Designed for precision-driven businesses across global markets, these machines blend cutting-edge technology, robust construction, and user-centric features to redefine productivity in diverse manufacturing scenarios. Whether you’re engaged in woodworking, advertising, metal fabrication, or creative industries, our ATC Function Middle Size CNC Machines deliver consistent performance that meets the highest standards of quality and reliability.

The ATC Function (Automatic Tool Changer) stands as the centerpiece of these middle size CNC machines, enabling seamless and rapid tool switching without manual intervention. This core feature drastically reduces downtime between operations, as the machine autonomously selects and replaces tools from its integrated tool magazine—eliminating human error and streamlining workflow. Each ATC Function Middle Size CNC Machine is equipped with a high-precision servo motor drive system, ensuring smooth XYZ axis movement with travel ranges optimized for middle size applications (up to 2000x3000x200mm) to handle a wide array of workpiece dimensions.

Crafted with durability in mind, these machines feature square rails for enhanced stability and load-bearing capacity, even during prolonged production runs. The water-cooled spindle (available in 3kw to 4.5kw options) operates at 0-24000 RPM, delivering powerful cutting and engraving capabilities while maintaining temperature control for consistent performance. The intuitive control system, paired with the ATC Function, allows operators to program complex tasks with ease, making the machine accessible to both seasoned professionals and skilled technicians new to CNC technology. Additionally, each ATC Function Middle Size CNC Machine adheres to strict quality control protocols, ensuring every unit meets Jinan Chentuo’s rigorous standards for reliability and longevity.

Our ATC Function Middle Size CNC Machines are engineered to excel in multiple industries, thanks to their adaptability and the flexibility of the ATC Function:

At Jinan Chentuo, we prioritize delivering value beyond equipment—our ATC Function Middle Size CNC Machines are backed by comprehensive pre-sales and after-sales support. From tailored technical consultations to remote troubleshooting and on-site training, our team is dedicated to helping you maximize the potential of your ATC Function-equipped machine. With exports to over 60 countries and partnerships with 200+ enterprises worldwide, our ATC Function Middle Size CNC Machines have earned a reputation for reliability in global markets.

The ATC Function is not just a feature—it’s a catalyst for operational excellence. By integrating this technology into our middle size CNC machines, we empower businesses to take on more complex projects, reduce lead times, and stay ahead of competitors in a fast-paced industry. Each ATC Function Middle Size CNC Machine is built to withstand the rigors of daily use, with durable components and easy maintenance that minimize downtime and extend machine lifespan.

Invest in Jinan Chentuo’s ATC Function Middle Size CNC Machines and experience the difference that precision, efficiency, and versatility can make for your business. Our commitment to superior quality, professional service, and innovative design ensures that your ATC Function machine will be a cornerstone of your production line for years to come. Partner with a trusted CNC leader—choose Jinan Chentuo for ATC Function Middle Size CNC Machines that deliver results, every time.

|

|

|

|

|

|

MDR controller(Ethernet port) Compared Mach3. its much easier to install and much more stable. Its a Professional CNC controller |

MPG Can help user control each axis move at slow speed. The other fabulous function is it can realize the simulation of procession. |

2.2kw ATC water cooling spindle Speed 24000 RPM ISO 20 tool holders ER20 collet:12.7mm tool max |

4pcs linear tool changers can meet most kind of work . save more time to changing tools |

|

|

|

|

|

|

Easy servo motor Closed loop motor has same encoder at back to communicate with driver. Without loosing steps. 30% higher performance than common stepper motor. |

High precision tool sensor Can get each different tool length offset . 0.001mm tolerance precision will help ATC machine work perfect |

Tool holder lock device Can help user change tool bits easily. |

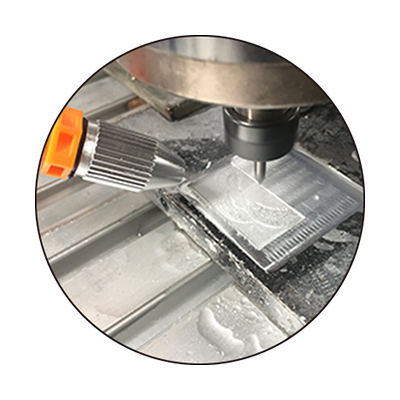

Ballscrew High precision is required to meet the C7 standard, ensuring the machine milling achieves high precision. |

|

|

|

|

|

|

Linear square guide ultra-heavy type that achieves a deep grooved raceway with its diameter more approximate to the ball diameter |

Vacuum table Multi-zoned allows the operator to easily switch from full sheet processing to smaller part processing. |

Embedded T slot User can use it to hold the material when no need vacuum absorption table working. |

Vacuum pump with vacuum gauge, primary and secondary filters, Automatic pressure relief function. |

|

|

|

|

|

|

Dust collector Powerful absorption capabitliy will make dust free environment. |

Schneider electrical part Well-know brand schneider Every details parts we choose top quality to confirm the machine steady and safe. |

|

|

|

|

|

|

| 3kw ATC water cooling spindle | NK105CS controller | Servo motor | Flood cooling for tool bits |

|

|

||

| Mist cooling for tool | Rotary device |

Answer: When your material is longer than the Y axis working length (but designed work is within), you can use this machine as well.

Answer: Gantry is aluminum casting and bed is iron casting. base is steel tube welded.

Answer: Yes, but need to add flood cooling system or mist cooling system.

Answer: Yes, we will make design according to customers request of working size . Any size we can make .

Answer: If you want to use rotary device instead of x or y. its ok. But if want to use 4axis .you need to replace controller to be 4axis . and add 4th driver. So it will be a little trouble. But we can offer our support.

Copyright © 2025 by Jinan Chentuo CNC Equipment Co.,Ltd. — Privacy Policy