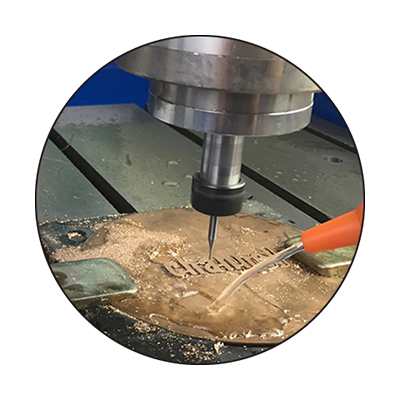

Mold and Die Making: Engraving cavities and textures into molds for plastic injection, die-casting, or glass making.

PCB (Printed Circuit Board) Manufacturing: Precise milling of copper boards to create circuit prototypes and small-batch production.

Functional Parts: Manufacturing precise, non-load-bearing parts from engineering plastics, epoxy boards, or soft metals for prototypes, fixtures, and jigs.

Main specifications

★ Iron casting structure

★ 2.2kw water cooling spindle

★ NCWORK controller with ethernet port

★ High precision stepper motor

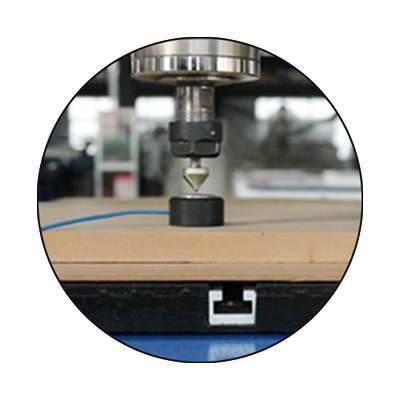

★ Square linear rails confirm higher precision

★ High precision ballscrew transimit

| Model | 4040 | 6060 |

| XYZ axis travel | 400x400x150mm | 600x600x150mm |

| Feeding height | 150mm | 150mm |

| Table size | 440x440mm | 660x660mm |

| Spindle | 2.2kw water cooling (0-24000RPM) | |

| Rail type | Square rail | |

| Control system | 3Axis NCWORK( Ethernet port) | |

| Motor | Stepper motor | |

| Transmit | Ballscrew | |

| Table type | Iron casting structure | |

| Max travel speed | 8000mm/min | |

| Working precision | 0.05mm | |

| Voltage | AC220V±10% / 50~60Hz | |

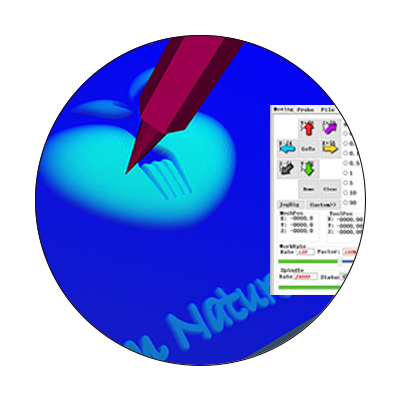

| Compatible Software | Type3/Artcam/UG/Pro-E/Mastercam/Ucancam etc | |

| Command code | G code | |

| Machine size (L*W*H) | 710*820*1320mm | 1050*1120*1320mm |

| packing size (L*W*H) | 880*940*1520mm | 1170*1120*1520mm |

| Net/Gross weight | 400kg / 450kg | 500kg / 550kg |

Jinan Chentuo CNC Equipment Co., Ltd., a seasoned expert with 16+ years in CNC technology, proudly presents the Strong Version 4040-6060PRO — a rugged, high-performance Metal CNC machine engineered to meet the demanding needs of B2B industrial users. Built for durability, precision, and versatility, this machine is tailored for businesses working with metal materials, delivering consistent results across cutting, engraving, and milling tasks. Whether you’re in automotive parts manufacturing, hardware production, or custom metal fabrication, the Strong Version 4040-6060PRO combines robust construction with advanced features to elevate your production efficiency, backed by our commitment to superior quality and customer service.

As a premium Metal CNC solution, the Strong Version 4040-6060PRO boasts features that prioritize power, accuracy, and long-term reliability. Available in two optimized models (4040 and 6060), the machine offers tailored XYZ axis travel distances: 400x400x140mm for the 4040 variant and 600x600x140mm for the 6060 variant, ensuring flexibility for both small-batch precision work and medium-scale metal processing. The feeding height of 140mm across both models accommodates thick metal sheets and workpieces, expanding its application range.

At its core, the Strong Version 4040-6060PRO is equipped with a 2.2kw water-cooling spindle (0-24000 RPM), delivering consistent torque and speed to handle tough metal materials like aluminum, copper, and steel with ease. Its square rail design, paired with a high-torque servo motor drive system, guarantees smooth, vibration-free movement — a critical factor for maintaining precision when working with hard metals. The machine also features the industry-trusted Mach3 control system, which offers intuitive operation, seamless CAD/CAM integration, and precise parameter adjustment, making complex metal processing tasks more manageable. Every component of the Strong Version 4040-6060PRO undergoes rigorous quality testing, reflecting our dedication to building Metal CNC machines that stand up to heavy industrial use.

The Strong Version 4040-6060PRO is a versatile Metal CNC machine that excels in diverse industrial scenarios, making it an asset for:

At Jinan Chentuo CNC Equipment Co., Ltd., we back the Strong Version 4040-6060PRO with comprehensive pre-sales and after-sales support, including free remote troubleshooting, on-site training, and insured shipping to 60+ countries. Our global presence and partnerships with 200+ enterprises attest to the quality and reliability of our Metal CNC machines. The Strong Version 4040-6060PRO isn’t just a tool — it’s a long-term investment that helps your business stay competitive in metal processing. Choose the Strong Version 4040-6060PRO and experience the difference a high-performance Metal CNC machine can make for your production capabilities.

|

|

|

|

| 2.2kw water cooling spindle | Inveter to control spindle speed | NCWORK controller | Tool sensor |

|

|

|

|

| Stepper motor | Square rails | High precision ballscrew | Flood tool cooling system |

|

|

|

|

| 3kw water cooling spindle | DSP controller | Servo motor | Easy servo motor |

Answer: This strong version is designed for customers who want better working result. so the iron casting structure is heavier and bigger thickness than light version. We will get less viberation during machining.

Answer: Absolutely! many customers dont know the the advantages of servo motors. if you dont know, please search on youtube or google . Shortly to say. servo motor wont loose steps. and less viberation during working. thats the key for metal milling.

Copyright © 2025 by Jinan Chentuo CNC Equipment Co.,Ltd. — Privacy Policy