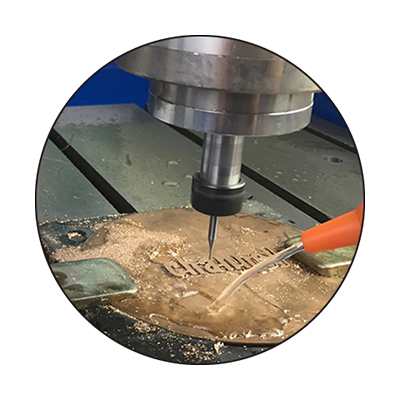

1.Advertisment industry:Acrylic,PVC,ABS plate,aluminum plate

2.General wood working industry:furniture decoration,instrument manufacturing,wooden craft,solid wood furniture,MDF

3.Decoration industry:art model,mural,screen,gift packing

4.Mould industry:casting,spaceflight,craft,rail traffic

Main specifications

★ 3.2kw water cooling spindle

★ Table move design .

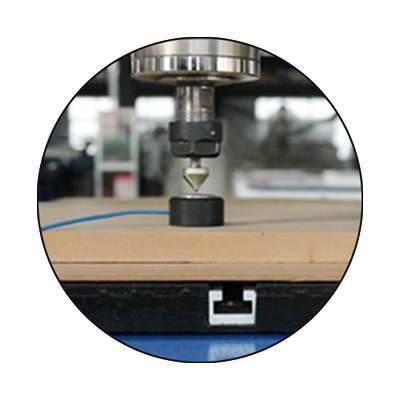

★ 400mmFeeding height

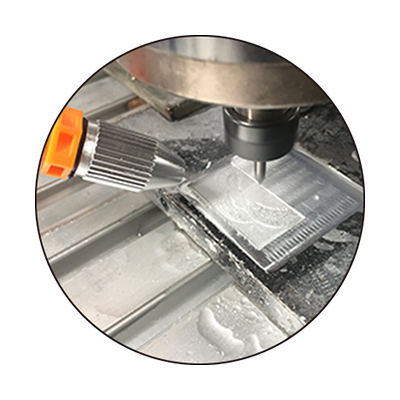

★ Square linear rails confirm higher precision

★ High precision ballscrew transimit

★ High precision stepper motor

| Model | 6050HZ |

| XYZ axis travel distance | 600x500x400mm |

| Feeding height | 400mm |

| Table size | 600x500mm |

| Spindle power | 2.2kw water cooling(0-24000RPM) |

| Rail type | linear rails |

| Control system | PC control system with ethernet port |

| Drive type | Stepper motor |

| Transmit | ballscrew |

| Table type | Aluminum table withT slot |

| Max travel speed | 6000mm/min |

| Working precision | 0.05mm |

| Power | AC220V±10%/50~60Hz |

| Compatible Software | Type3/Artcam/UG/Pro-E/Mastercam/Ucancam etc |

| Command code | G code |

| Machine size | 1.22*1.17*1.48m |

| Packing size | 1.36*1.31*1.68m |

| Net / Gross weight | 300kg / 350kg |

As a leading name in CNC equipment manufacturing with over 16 years of industry expertise, Jinan Chentuo CNC Equipment Co., Ltd. takes pride in presenting the High Feeding Model — a game-changing middle size CNC line designed to redefine efficiency, precision, and versatility for B2B clients worldwide. Engineered to meet the diverse demands of modern manufacturing, this High Feeding Model stands out as a reliable partner for businesses seeking to boost productivity without compromising on quality. Whether you’re in woodworking, advertising, decoration, or metal processing, this middle size High Feeding Model delivers consistent performance that aligns with your most ambitious production goals.

The High Feeding Model is built with cutting-edge features that set it apart in the middle size CNC segment, ensuring it meets the rigorous standards of professional manufacturers. At its core, the High Feeding Model boasts an impressive feeding height, ranging from 110mm to 200mm across different configurations, allowing it to handle thicker materials and larger workpieces with ease — a critical advantage for projects that demand substantial material capacity. Complemented by a robust table size (from 320x580mm to 2000x3000mm), the High Feeding Model provides ample workspace to accommodate diverse production needs, from small-batch crafts to large-scale industrial runs.

Equipped with high-performance spindle options (1.5kw to 4.5kw) — including water cooling and air cooling variants — the High Feeding Model delivers exceptional rotational speeds (0-18000 RPM to 0-24000 RPM), ensuring smooth, precise cutting, engraving, and milling across a wide range of materials. The integration of servo motors and square rails enhances stability and accuracy, minimizing vibration and ensuring consistent results even during long production cycles. Additionally, advanced control systems such as MDR + CCD, Mach3, and NCW optimize operational efficiency, making the High Feeding Model intuitive to operate while maximizing output. Every component of the High Feeding Model is rigorously tested by our quality control team, guaranteeing durability and reliability that stands the test of time.

Choosing the High Feeding Model means investing in a solution that offers tangible business benefits, designed to give you a competitive edge in the market. First and foremost, the High Feeding Model’s exceptional feeding capacity translates to reduced downtime — you can process thicker, larger materials in fewer passes, significantly speeding up production timelines and increasing throughput. This efficiency boost directly impacts your bottom line, allowing you to take on more orders and meet tight deadlines with confidence.

Another key advantage of the High Feeding Model is its versatility. Engineered to work seamlessly with a wide array of materials, it eliminates the need for multiple specialized machines, reducing equipment costs and streamlining your workflow. The model’s robust construction, paired with Jinan Chentuo’s strict quality control, ensures long-term reliability with minimal maintenance, lowering operational costs and maximizing return on investment. Additionally, the High Feeding Model is backed by our professional pre-sales and after-sales service, including free remote support and optional on-site training, ensuring you get the most out of your equipment from day one. With the High Feeding Model, you’re not just buying a CNC machine — you’re partnering with a team dedicated to your success.

The High Feeding Model’s flexibility makes it an indispensable tool across numerous industries, adapting to a wide range of production needs:

At Jinan Chentuo CNC Equipment Co., Ltd., we’ve designed the High Feeding Model to be more than just a machine — it’s a catalyst for growth, innovation, and success. With its exceptional features, unmatched advantages, and diverse applications, this middle size High Feeding Model is the perfect choice for businesses looking to elevate their production capabilities. Backed by our 16+ years of CNC expertise, global presence in over 60 countries, and commitment to quality and service, the High Feeding Model delivers the performance and reliability you need to thrive in today’s competitive market. Invest in the High Feeding Model and experience the difference that a professional, high-quality CNC solution can make for your business.

|

|

|

|

| 2.2kw water cooling spindle | Inveter to control spindle speed | NCWORK controller | Tool sensor |

|

|

|

|

| Stepper motor | Square rails | High precision ballscrew transmision | T slot table |

|

|

|

|

| 3kw water cooling spindle | 3kw air cooling spindle | DSP controller | NK105G3 controller |

|

|

|

|

| Easy servo motor | Servo motor | Vacuum table | Dust collector |

|

|

|

|

| Flood cooling for tool bits | Mist cooling for tool bits | Rortary device |

Answer: Yes, but need to add flood cooling system or mist cooling system.

Answer: Yes, we will make design according to customers request of working size . Any size we can make .

Answer: If you want to use rotary device instead of x or y. its ok. But if want to use 4axis .you need to replace controller to be 4axis . and add 4th driver. So it will be a little trouble. But we can offer our support.

Copyright © 2025 by Jinan Chentuo CNC Equipment Co.,Ltd. — Privacy Policy