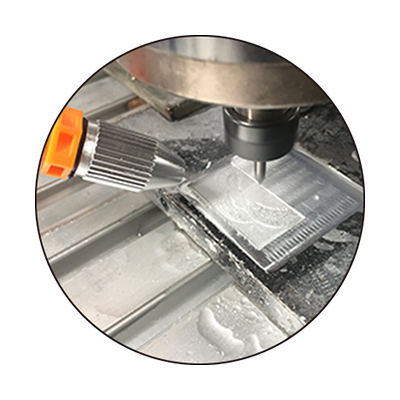

1.Advertisment industry:Acrylic,PVC,ABS plate,aluminum plate

2.General wood working industry:furniture decoration,instrument manufacturing,wooden craft,solid wood furniture,MDF

3.Decoration industry:art model,mural,screen,gift packing

4.Mould industry:casting,spaceflight,craft,rail traffic

Main specifications

★ 2.2kw water cooling spindle

★ PC control system with ethernet port

★ High precision stepper motor

★ Square linear rails confirm higher precision

★ High precision ballscrew transimit

★ Vacuum table / dust collector option

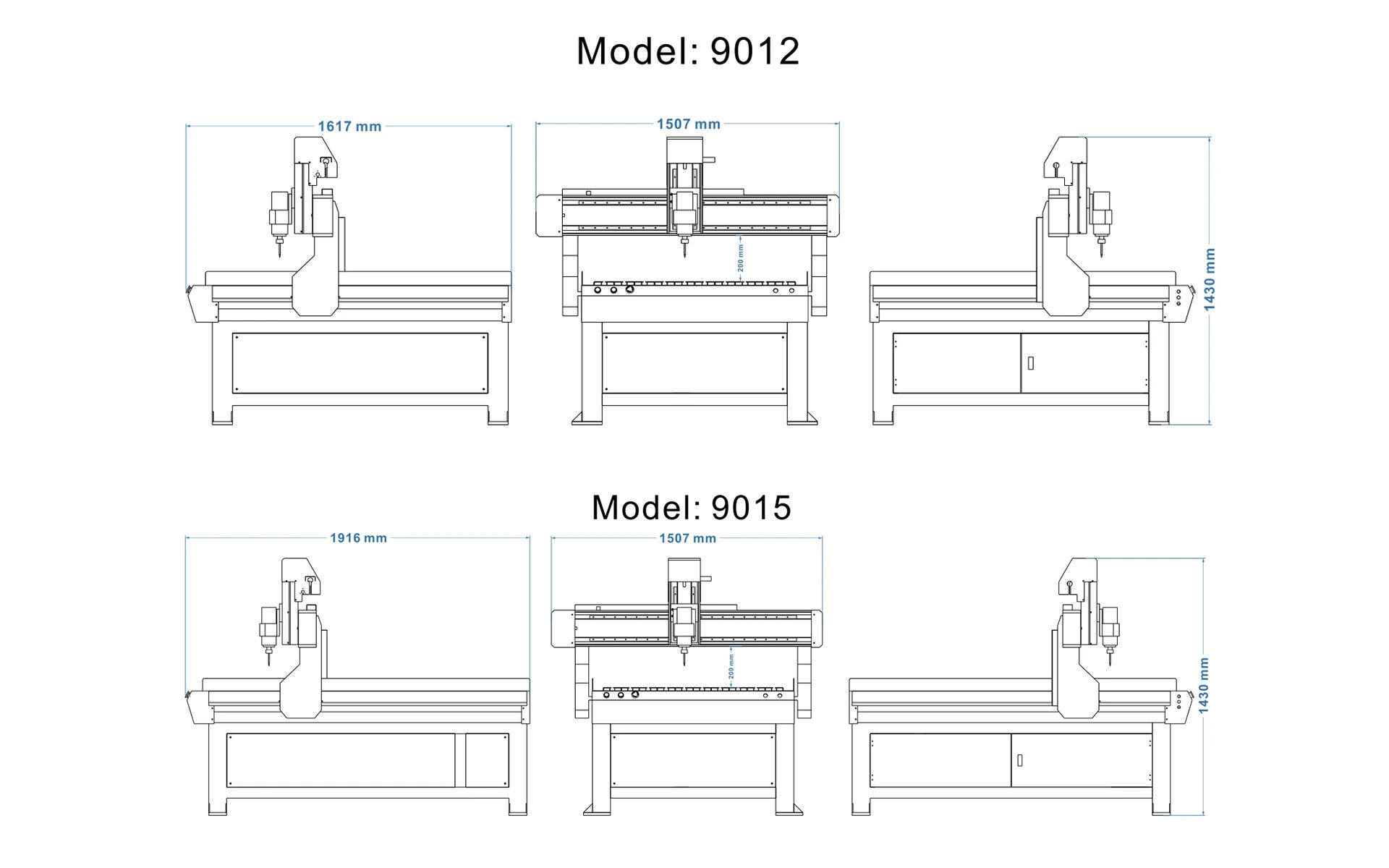

| Model | 9012 | 9015 |

| XYZ axis travel | 900x1200x180mm | 900x1500x180mm |

| Feeding height | 200mm | 200mm |

| Table size | 1300x1250mm | 1300x1520mm |

| Spindle | 2.2kw water cooling (0-24000RPM) | |

| Rail type | Square rail | |

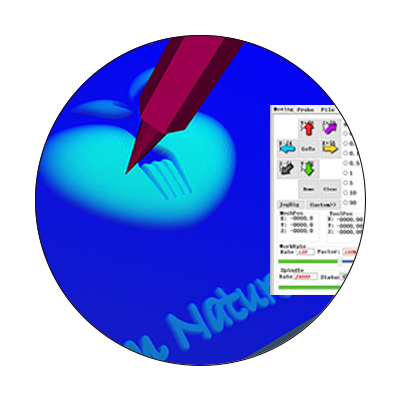

| Control system | PC control system with ethernet port | |

| Motor | Stepper motor | |

| Transmit | Ballscrew | |

| Table type | Aluminum profile T slot clamping | |

| Max travel speed | 8000mm/min | |

| Working precision | 0.05mm | |

| Voltage | AC220V±10% / 50~60Hz | |

| Compatible Software | Type3/Artcam/UG/Pro-E/Mastercam/Ucancam etc | |

| Command code | G code | |

| Machine size (L*W*H) | 1680*1420*1420mm | 1980*1420*1420mm |

| packing size (L*W*H) | 1850*1620*1600mm | 2150*1620*1600mm |

| Net/Gross weight | 400kg / 450kg | 500kg / 550kg |

With over 16 years of pioneering experience in the CNC industry, Jinan Chentuo CNC Equipment Co., Ltd. proudly presents the 90 Series — a line of high-performance middle size CNC machines engineered to deliver unmatched precision, versatility, and efficiency for B2B manufacturers worldwide. Designed to meet the evolving demands of modern production, the 90 Series encompasses CNC routers, laser cutters, and engraving systems that excel in handling diverse materials and complex tasks. Whether you’re a small workshop or a large-scale industrial facility, the 90 Series adapts to your unique needs, combining robust construction with advanced technology to drive productivity and profitability. Trust in a legacy of CNC excellence, where every 90 Series machine is built to exceed industry standards and empower your business growth.

The 90 Series stands as a benchmark for middle size CNC equipment, packed with features that prioritize performance, durability, and user-friendliness. At the heart of each 90 Series machine is a high-power spindle — available in 2.2kw water cooling and 4.5kw air cooling variants — delivering rotational speeds up to 24000 RPM for smooth, precise cutting, engraving, and milling. This spindle works in tandem with square rails and servo motor drives, ensuring exceptional stability and minimal vibration even during long production runs, resulting in consistent, high-quality outputs.

Each 90 Series model boasts a spacious worktable (ranging from 600x900mm to 600x1270mm) and a generous feeding height of 140mm to 150mm, accommodating large workpieces and thick materials with ease. The integration of intuitive control systems, including Mach3 and NCW, simplifies operation, allowing both seasoned operators and new users to navigate complex tasks with confidence. Additionally, the 90 Series features a rugged, corrosion-resistant frame crafted from high-grade steel, ensuring longevity and reliability in harsh industrial environments. Every component of the 90 Series undergoes rigorous quality testing, reflecting Jinan Chentuo’s commitment to delivering machines that minimize downtime and maximize productivity.

Investing in the 90 Series means unlocking a host of advantages that give your business a competitive edge in the global market. First and foremost, the 90 Series’ exceptional precision translates to superior workpiece quality, with crisp details, smooth finishes, and tight tolerances that meet the most demanding client requirements. This level of quality reduces rework and material waste, directly boosting your bottom line and enhancing customer satisfaction.

Versatility is another key advantage of the 90 Series. These middle size machines handle a wide spectrum of materials — from wood, acrylic, and PVC to aluminum, steel, and stone — eliminating the need for multiple specialized tools and streamlining your workflow. The 90 Series’ efficient design also contributes to faster production cycles, with high spindle speeds and responsive controls that reduce processing time without compromising quality. Backed by Jinan Chentuo’s comprehensive support, including free remote service, optional on-site training, and global shipping with insurance, the 90 Series ensures you receive maximum value from your investment. For businesses expanding into new markets, the 90 Series’ reputation for reliability and performance opens doors to international opportunities, as evidenced by our presence in over 60 countries worldwide.

The 90 Series’ flexibility makes it an indispensable tool across numerous industries, adapting to diverse production needs with ease:

Jinan Chentuo’s 90 Series is more than just a line of middle size CNC machines — it’s a strategic asset that drives innovation, efficiency, and growth for your business. With its exceptional features, standout advantages, and wide-ranging applications, the 90 Series is tailored to meet the needs of modern B2B manufacturers. Backed by 16+ years of CNC expertise, a global network of satisfied clients, and a commitment to excellence, the 90 Series delivers the performance and reliability you need to thrive in today’s competitive market. Choose the 90 Series and experience the difference that professional, high-quality CNC equipment can make for your operations.

|

|

|

|

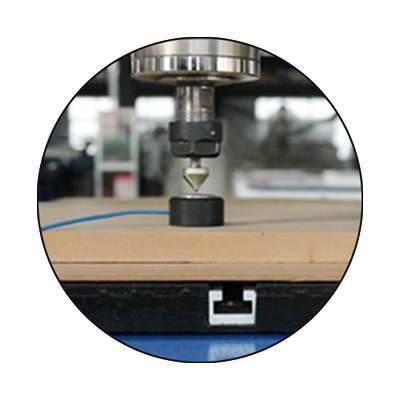

| 2.2kw water cooling spindle | Inveter to control spindle speed | NCWORK controller | Tool sensor |

|

|

|

|

| Stepper motor | Square rails | High precision ballscrew transmision | T slot table |

|

|

|

|

| 3kw water cooling spindle | 3kw air cooling spindle | DSP controller | NK105G3 controller |

|

|

|

|

| Easy servo motor | Servo motor | Vacuum table | Dust collector |

|

|

|

|

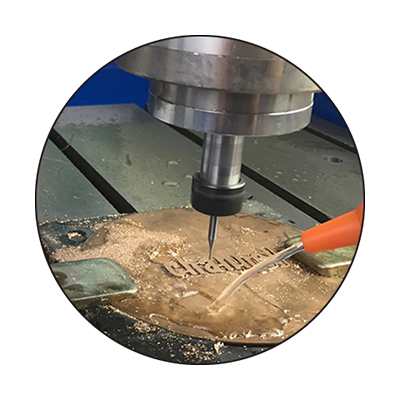

| Flood cooling for tool bits | Mist cooling for tool bits | Rortary device |

Answer: Gantry is aluminum casting and bed is iron casting. base is steel tube welded.

Answer: Yes, but need to add flood cooling system or mist cooling system.

Answer: Yes, we will make design according to customers request of working size . Any size we can make .

Answer: If you want to use rotary device instead of x or y. its ok. But if want to use 4axis .you need to replace controller to be 4axis . and add 4th driver. So it will be a little trouble. But we can offer our support.

Copyright © 2025 by Jinan Chentuo CNC Equipment Co.,Ltd. — Privacy Policy