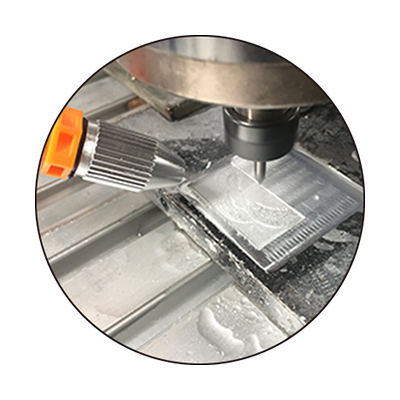

1.Advertisment industry:Acrylic,PVC,ABS plate,aluminum plate

2.General wood working industry:furniture decoration,instrument manufacturing,wooden craft,solid wood furniture,MDF

3.Decoration industry:art model,mural,screen,gift packing

4.Mould industry:casting,spaceflight,craft,rail traffic

Main specifications

★ 2.2kw water cooling spindle

★ Controller with ethernet port

★ High precision stepper motor

★ Square linear rails confirm higher precision

★ High precision ballscrew transimit

★ Vacuum table / dust collector option

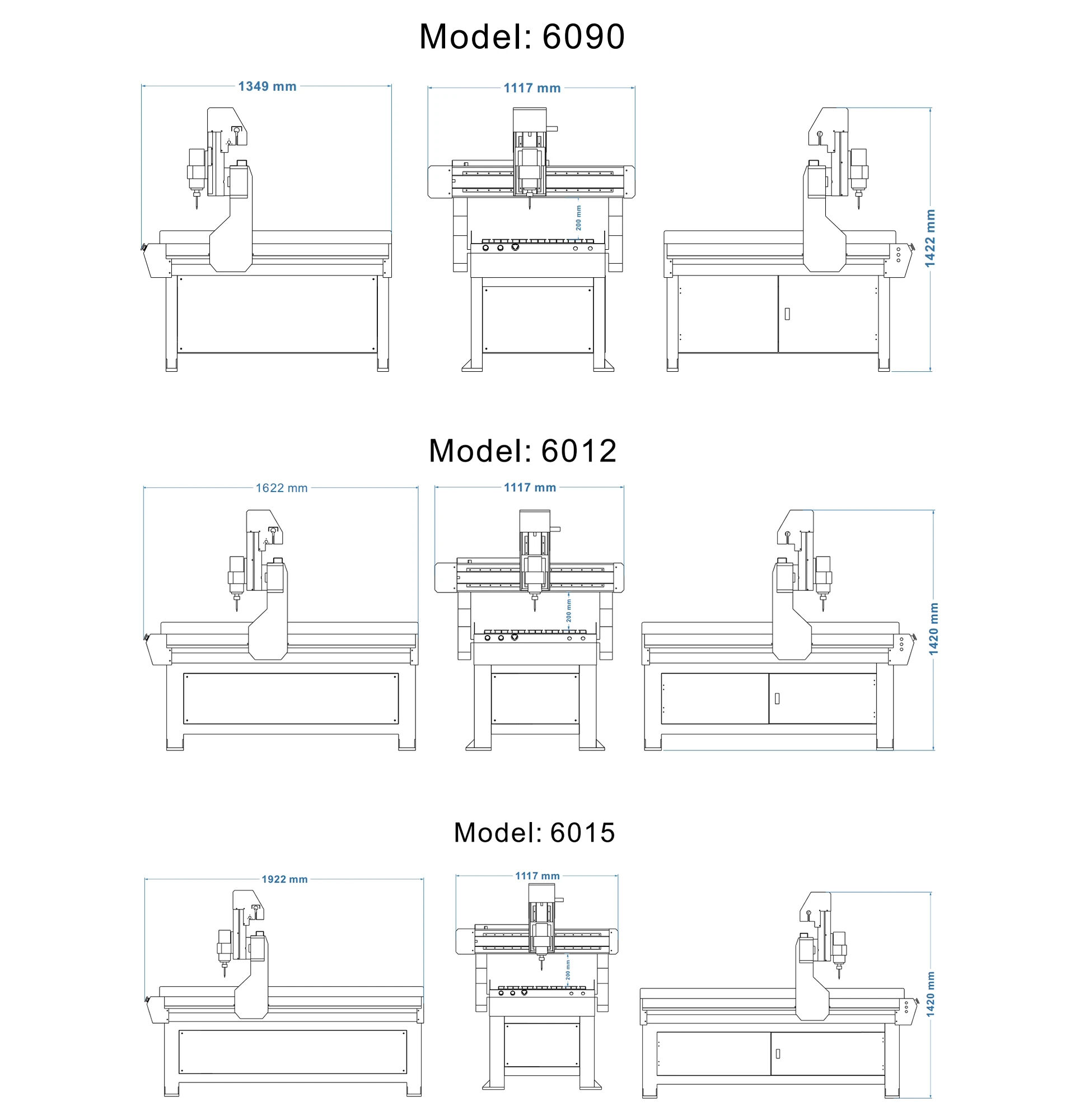

| Model | 6090 | 6012 | 6015 |

| XYZ axis travel | 600x900x180mm | 600x1200x180mm | 600x1500x180mm |

| Feeding height | 200mm | 200mm | 200mm |

| Table size | 600x1250mm | 600x1550mm | 600x1850mm |

| Spindle | 2.2kw water cooling (0-24000RPM) | ||

| Rail type | Square rail | ||

| Control system | PC control system with ethernet port | ||

| Motor | Stepper motor | ||

| Transmit | Ballscrew | ||

| Table type | Aluminum profile T slot clamping | ||

| Max travel speed | 8000mm/min | ||

| Working precision | 0.05mm | ||

| Voltage | AC220V±10% / 50~60Hz | ||

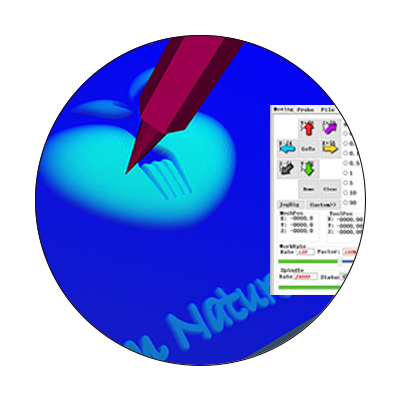

| Compatible Software | Type3/Artcam/UG/Pro-E/Mastercam/Ucancam etc | ||

| Command code | G code | ||

| Machine size (L*W*H) | 1380*1120*1420mm | 1680*1120*1420mm | 1980*1120*1420mm |

| packing size (L*W*H) | 1520*1220*1600mm | 1790*1220*1600mm | 2090*1220*1600mm |

| Net/Gross weight | 300kg / 350kg | 350kg / 400kg | 400kg / 450kg |

For B2B businesses in search of reliable, high-performance middle size CNC solutions, Jinan Chentuo CNC Equipment Co., Ltd. introduces the 60 Series Middle Size CNC Machines—craftedin with 16+ years of industry expertise to redefine productivity across global manufacturing sectors. Engineered for versatility, durability, and operational excellence, the 60 Series stands as a trusted choice for enterprises seeking to elevate their production capabilities. Whether you operate in woodworking, advertising, metal fabrication, or creative industries, the 60 Series Middle Size CNC Machines deliver consistent, high-quality results that meet the demands of modern manufacturing.

The 60 Series Middle Size CNC Machines are packed with features designed to optimize performance and user experience. Available in two robust models—6040Z and 6090Z—the 60 Series offers tailored solutions for diverse middle size project needs. The XYZ axis travel distances (600x400x140mm for 6040Z and 600x900x140mm for 6090Z) provide ample workspace to handle a wide range of workpiece dimensions, while the 140mm feeding height accommodates thicker materials with ease.

Each 60 Series machine is equipped with a 2.2kw water-cooled spindle operating at 0-24000 RPM, delivering powerful cutting, engraving, and milling capabilities across various substrates. The square rails design ensures exceptional stability and load-bearing capacity, minimizing vibration during prolonged production runs for consistent precision. The intuitive Mach3 control system simplifies programming and operation, making the 60 Series accessible to both seasoned professionals and skilled technicians. Additionally, the 60 Series features spacious table sizes (400x970mm for 6040Z and 600x1270mm for 6090Z), providing ample support for workpieces while maintaining optimal cutting accuracy. Every 60 Series Middle Size CNC Machine undergoes strict quality control inspections, ensuring it meets Jinan Chentuo’s rigorous standards for reliability and longevity.

The 60 Series Middle Size CNC Machines excel in multiple industries, offering adaptability that meets the unique demands of each sector:

Jinan Chentuo’s commitment to excellence extends beyond the 60 Series’ technical capabilities—we provide comprehensive support to B2B partners worldwide. With products exported to 60+ countries and partnerships with 200+ enterprises, our reputation for superior quality and professional service is globally recognized. The 60 Series benefits from our rigorous quality control processes, ensuring each machine arrives in optimal condition and performs consistently for years.

Our pre-sales and after-sales services include technical consultations, free remote troubleshooting, and low-cost on-site training, ensuring you maximize the potential of your 60 Series machine from day one. The 60 Series is not just a tool—it’s a long-term investment in your business’s growth, offering the performance and reliability needed to stay competitive in dynamic markets.

The 60 Series Middle Size CNC Machines embody Jinan Chentuo’s principle of “excellent quality, excellent service.” By choosing the 60 Series, you partner with a trusted CNC leader that prioritizes your success, delivering a machine that combines precision, versatility, and efficiency to drive your production forward. Whether you’re scaling your operations or expanding into new markets, the 60 Series Middle Size CNC Machines are engineered to meet your evolving needs and exceed your expectations. Invest in the 60 Series today and experience the difference that 16+ years of CNC expertise can make for your business.

|

|

|

|

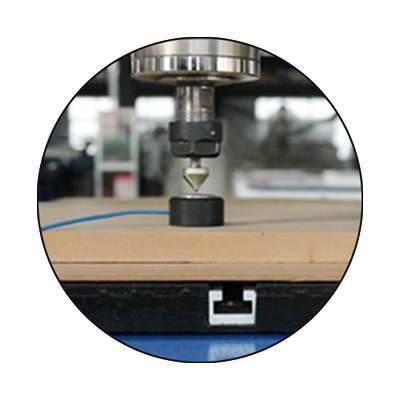

| 2.2kw water cooling spindle | Inveter to control spindle speed | NCWORK controller | Tool sensor |

|

|

|

|

| Stepper motor | Square rails | High precision ballscrew transmision | T slot table |

|

|

|

|

| 3kw water cooling spindle | 3kw air cooling spindle | DSP controller | NK105G3 controller |

|

|

|

|

| Easy servo motor | Servo motor | Vacuum table | Dust collector |

|

|

|

|

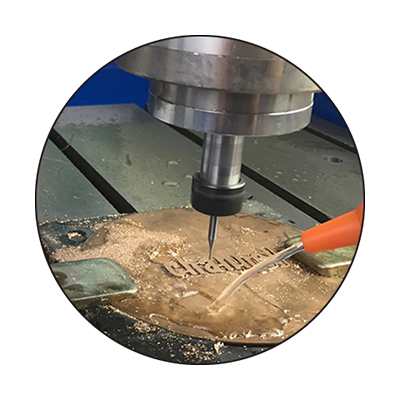

| Flood cooling for tool bits | Mist cooling for tool bits | Rortary device |

Answer: Gantry is aluminum casting and bed is iron casting. base is steel tube welded.

Answer: Yes, but need to add flood cooling system or mist cooling system.

Answer: Yes, we will make design according to customers request of working size . Any size we can make .

Answer: If you want to use rotary device instead of x or y. its ok. But if want to use 4axis .you need to replace controller to be 4axis . and add 4th driver. So it will be a little trouble. But we can offer our support.

Copyright © 2025 by Jinan Chentuo CNC Equipment Co.,Ltd. — Privacy Policy